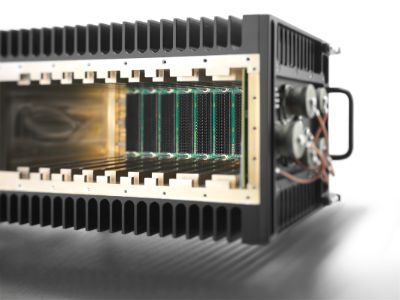

ATR (Air Transport Rack)

The most rugged packaging for computing

The Air Transportation Rack (ATR) is the de-facto standard form factor for aircraft board electronic equipment since more than 50 years. The two ARINC drawings SK-141-10 and the SK-141-17 with detailed critical dimensions and tolerances for the initial 3 basic form factors, via the ½, 1 and 1 ½ ATR became the basis for ARINC 404A as it is used even today.

Additional Information

ARINC 404 specifies mechanical dimensions of Line Replaceable Units (or LRU’s) and their mounting systems in different locations of an aircraft. LRU’s are installed on specially designed trays, which provide mechanical support but optionally also shock absorption, cooling and plug-in capability.

ATR’s are increasingly being deployed in wheeled and tracked ground vehicles and also used in shipboard applications. Each application is subject to its own array of harsh environmental factors including shock, vibration, temperature, moisture and salt, that need to be taken into consideration. Today ATR’s are introduced into applications imagined never before, including surveillance, data collection, storage and weapons control. Convection and Conduction cooled ATR (Air Transport Rack) enclosures offer a standardized, cost effective solution for PCI, VME, VME64x, VXS, cPCI and VPX based applications. Available in 1/2, 3/4, 1 and 1 1/2 ATR tall long or tall short formats per ARINC 404A, ARINC 600 and IEEE 1101.10 specifications, the modular design concept allows for a wide range of customization options without the cost and lead time penalties associated with custom designs.

Typically ATR’s are made from punched and formed aluminum sheets and milled plates or brazed aluminum. A removable front panel allows I/O customization to exact application requirements and increased configurability. The ATR enclosures use electrostatic dust filters, honeycomb EMI filters and a narrow screw spacing to seal off every external seam to ensure compliance to MIL-STD-461. The rugged designs meet the requirement for shock, vibration and structural integrity per MIL-STD-810, MIL-STD-167 and MIL-STD-901D

Related Standards:

- MIL-STD-5400: General standard for Aerospace Electronic Equipment

- MIL-STD-810: Environmental Test Methods and Engineering Guidelines

- MIL-STD-46I: Requirements for the control of EMI Emissions and Susceptibility

- MIL-STD-704: Aircraft Electric Power Characteristics

- MIL-STD-1275: Characteristics of 28 VDC Electrical Systems in Military Vehicles

- RTCA/DO-160:

Chassis width is measured in fractions of ATR, when 1ATR means the width of the enclosure is 10.12” and it will fit into a 1 ATR tray. Typically there are 2 options of length (L) – Short ATR (12.62”) and Long ATR (19.52”). There are also several standard options of the height of the chassis (regular – 7.62”, or “Tall” – 10.62”). In addition to mechanical dimensions, the standard also defines fixture hardware locations for given width of the chassis.

Contact Us

Discover how Hartmann can increase power, speed and rugged durability to your project performance.

Hartmann Electronic

Motorstr. 43

D-70499 Stuttgart, Germany

202 N. Limestone St. Suite 320

Springfield, Ohio 45503